When we first started putting on our show, we made our own mortar racks. They were heavy because they were over designed and they had 48 tubes in each rack (6 rows of 8).

One day I saw a new rack on the market. The OctoRack. They were billed as lighter, stronger, and best of all, the parts were CNC machined! I ordered 8 of the 18-Shot straight racks (enough to re-home the 144 tubes we already had.) Well, turns out Pyroboom had jumped the gun on promoting this new product. First they underpriced it (they still honored the price I paid for the first 8). Then they had significant issues getting the pieces cut on their CNC router. So, all in all, they failed to ship product for months and we missed the 2024 show. The racks did come in and we liked them so much we bought 4 more 18-shot straight (this time with tubes) and 4 18-shot adjustable (also with tubes). This would give us 324 2″ mortars!

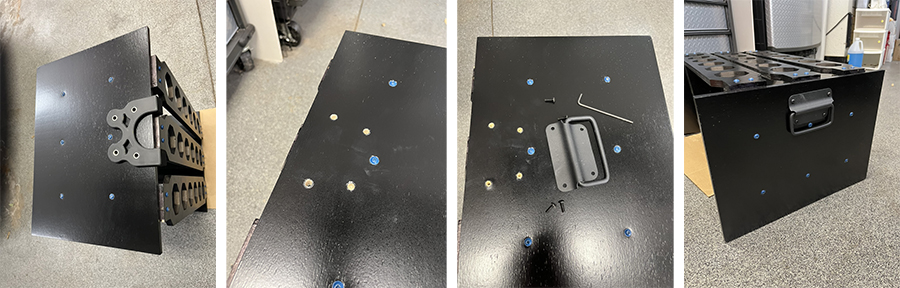

The racks come unfinished, so we are painting them black, mostly to protect them from the elements so they’ll last a long time, but also to look bad ass.

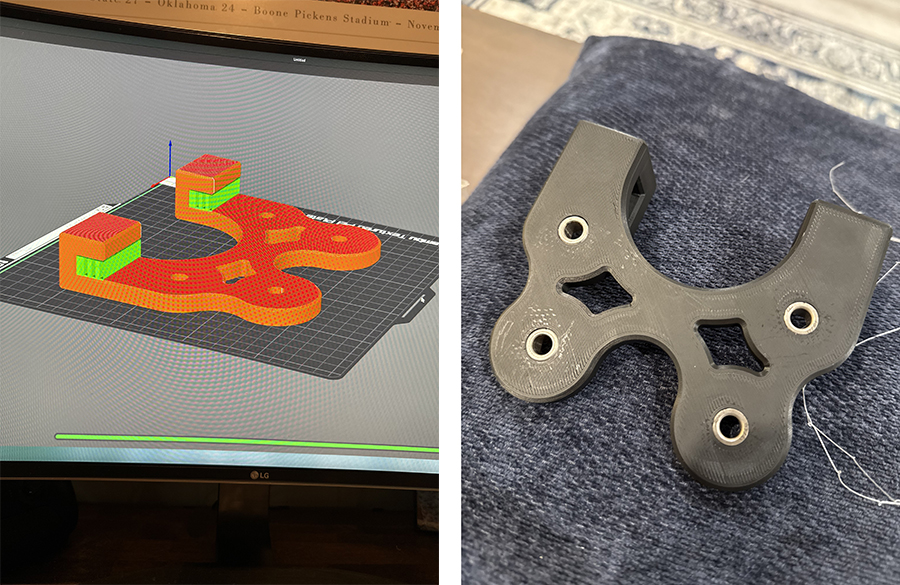

We will add handles to each end to make them easy to carry. The ends are 1/2″ plywood. To ensure that the handles are sturdy and we don’t eventually tear the screws out, we are using 8-32 threaded inserts. It takes 4 screws for each handle, 2 handles for each rack, and 18 racks means measuring and drilling 144 holes. So, we designed and 3D printed a drill guide.

Each hole accepts a drill bushing for the 17/64 drill to create holes for the inserts.

Then we will stencil the PYROT3CH logo on them in orange:

So it will look like this: